| Parameter | Unit |

| Ход оси Х | мм |

| Ход оси Y | мм |

| Ход оси Z | мм |

| размеры стола | мм |

| Макс.усилие на рабочий стол | кг |

| обороты шпинделя | об/мин |

| конусность шпинделя | |

| двигатель шпинделя | кВт |

| максимальный диаметр инструмента | мм |

| длина инструмента | мм |

| вес инструмента | кг |

| система охлаждающего резервуара | л |

| вес станка | кг |

MV154E MV154P 700 530 560 900x500 500 9000 12000 15000 BBT40 15 76.2 280 7 400 6400 700 530 560 900x500 500 9000 12000 15000 BBT40 22 76.2 280 7 400 6400

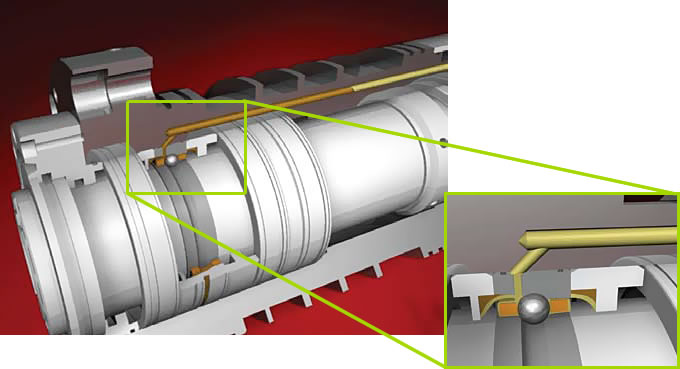

The grease chamber volume at 7.5 cm3 can support 28,840 hr.

This LUBCON unit service life at 3 years as minimum is guaranteed.

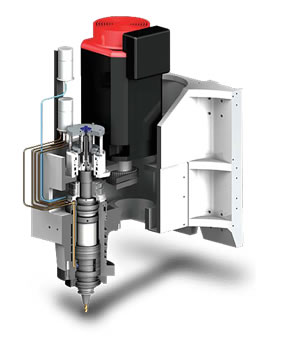

TYPES OF SPINDLE:

Belt spindle

- Transmission: Belt driving

- Lubrication: Re-grease system

- 12,000 min-1, vibration 1.5μm with low noise level plus very low maintenance cost.

- 4 hybrid angular bearing plus one roller bearing in rear.

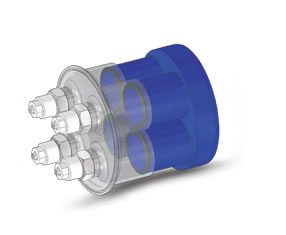

Coupling spindle

- Transmission: Coupling

- Lubrication: Re-grease system

- Highest rigidity 15,000 min-1 spindle.

- 4 ceramic ball bearing .

- Transmission: Coupling

- Lubrication: Grease packed system

- 8,000 min-1 spindle.

- 10,000 min-1 spindle(opt.)

- 12,000 min-1 spindle(opt.)

- 4 ball bearing large span

Positioning accuracy=1.180 µ m VDI 3441

Feed rate: 500 mm / min, Value: 1.1µm

Wide-spaced, oversized linear guideways provide optimum stiffness with less friction, less heat and less thermal growth for faster traverse rates, longer machine life and greater positioning accuracy.

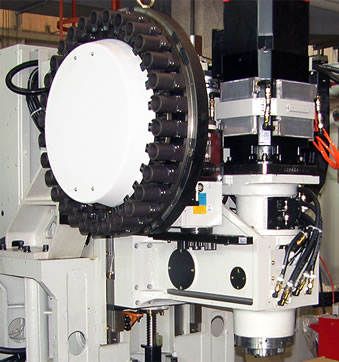

ATC system is designed for large capacity and fast performance. To ensure smooth and vibration-free tool changing, all MV-Series machines have their tool changer strategically located for minimal transfer of vibration—a unique design feature. All ATCs feature random-access, bi-directional indexing.

Chips removal

Dual auger + main conveyor at the back for large volume swarf management.

Highly engineered column structure manufactured from grey cast iron, heavily ribbed to ensure high overall rigidity and thermal stability.

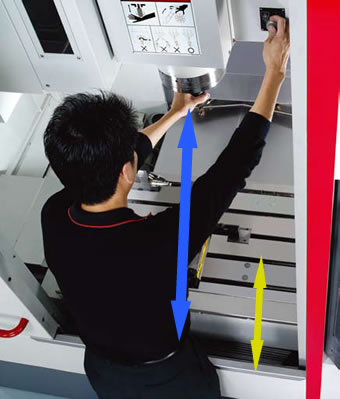

Machine Operation

Swiveling operator panel.

Single door design open at

- MV154: 900 (mm)

- MV184: 1,150 (mm)

Easy loading of large work piece

Spindle to front at a convenient

- MV154: 753 (mm)

- MV184: 870 (mm)

Table to front-easy access

- MV154: 168 (mm)

- MV184: 265 (mm)

CNC Control:

FANUC

- QUASER MILL i (for E type)

- 18iM-B (for P type)

- 31iA (for M type)

HEIDENHAIN

- iTNC530 (for P & M type)